Innovations that reduce costs are a major barrier to overcome in the race to deploy floating wind and marine energy commercially.

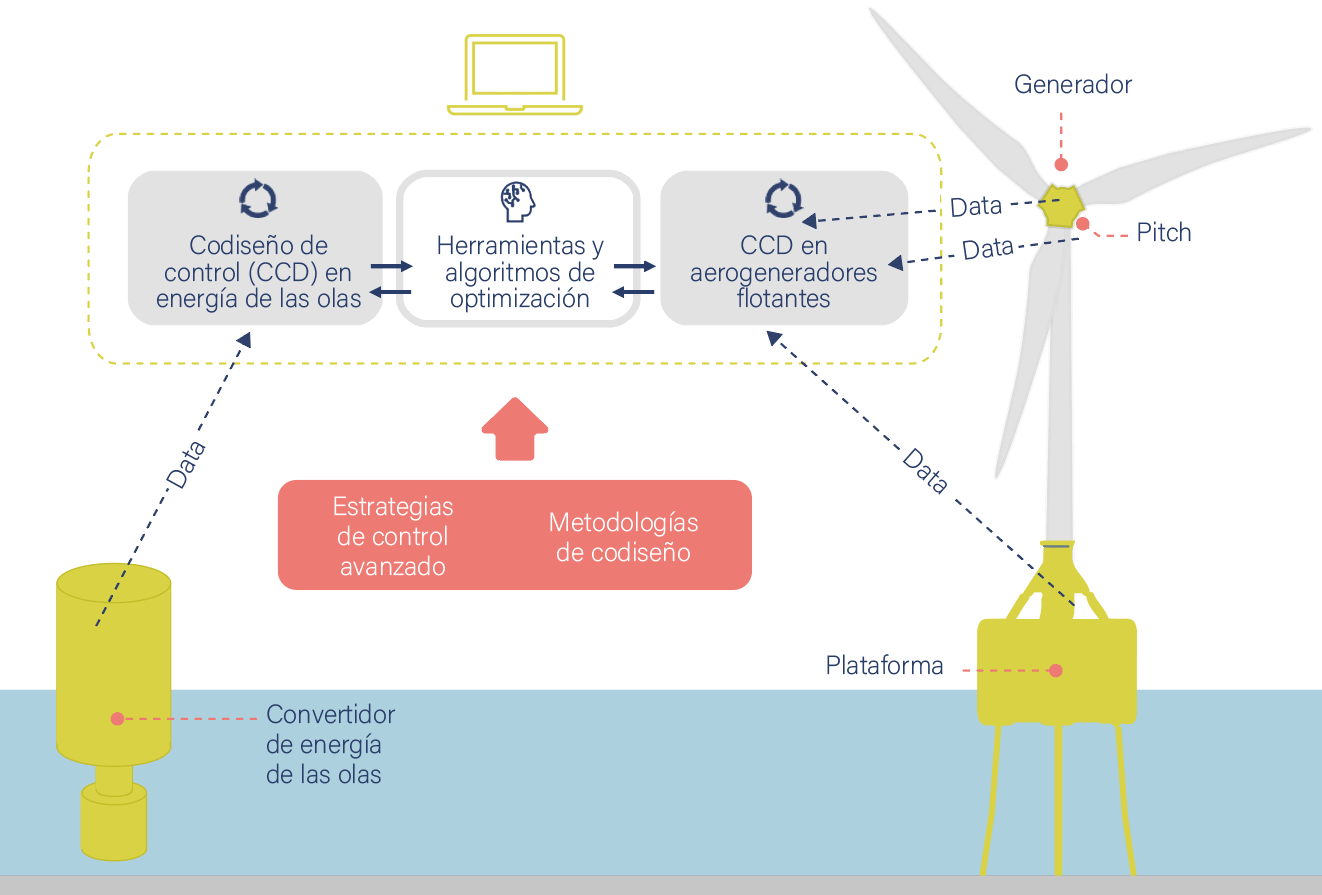

One of the ways to tackle this challenge is to develop the supply chain; another involves optimising designs. KONFLOT's areas of work are focused on this last point. Costs can be reduced by developing optimised technologies through control co-design (CCD), with control strategies at the heart of the design.

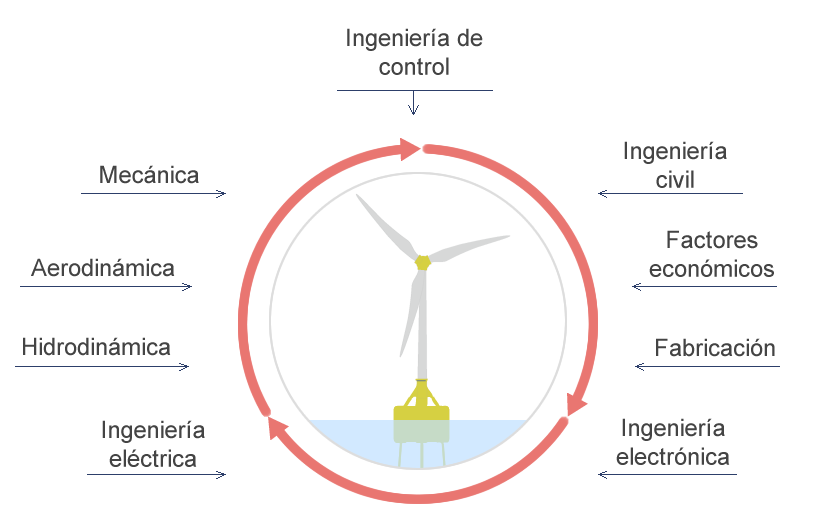

Traditionally, the design of floating wind turbines and wave energy harvesters has been done sequentially, starting with a structural design and looking at control systems only in the later stages of the design. Consequently, each design stage is constrained by the previous stage and the controls developed in the last stage (wind turbine, energy extraction system, active ballast, etc.) have a very small impact on optimising the entire system.

Scope of the project

KONFLOT uses a concurrent process to tackle the challenge of considering the different subsystems, their dynamics and interactions, and the control actions available from the earliest design phases, so that it can come up with ground-breaking alternatives that could not be achieved in sequential design processes.